Published on 06/06/2011

First Update 16/03/2017

Domestic/municipal wastewater and many industrial effluents contain significant amounts of biodegradable organic wastes. Organic pollutants are most economically treated by biological methods, wherein microbes convert them to inert biomass that can be precipitated out and eliminated from the wastewater. Biological treatment is essentially of two types- aerobic and anaerobic. In comparison to aerobic biodegradation, anaerobic treatment, where applicable, is often more advantageous.

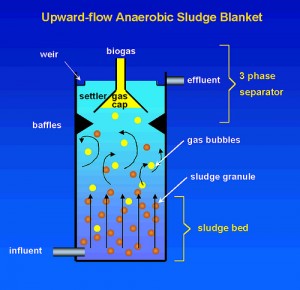

One or the economic and effective anaerobic treatment method is the UASB (Upflow Anerobic Sludge Blanket) process. In a UASB Reactor wastewater is fed from the bottom. As it flows upward through the reactor, organic matter in the waste is degraded anaerobically by micro organisms resident in the sludge blanket. Besides converting organics to cell mass, biogas rich in methane is produced as a by product. A Gas Liquid Solid separator(GLSS) provided near the top of the reactor, enables sludge to settle into the blanket, biogas to escape into the dome at the top of the reactor, and treated supernatant to flow out of the reactor. High sludge concentration in sludge blanket and low concentration of suspended solids in the reactor over flow are characteristic features of a good UASBR.

The basic advantages of a UASBR over aerobic treatment units are :

* UASBR in a compact unit, ideal for economic space utilization.

* UASB treatment process requires no external input of energy. Even the required mixing is achieve by upflowing waste water and rising gas bubbles.

* Nutrient requirement (i.e. N&P) is muc less than (about half that needed ) for aerobic treatment.

* Residuals (i.e.sludge) generated by UASB treatmet are much less in amount and well digested, requiring reduced sludge hanldling and causing much less odour problems.

The UASBR comprises no mechanical or moving part involving wear and tear. Thus it is virtually maintenance free and involves few operational problems. When properly designed and made, a UASBR provides trouble-free service for many years.

* Biogas, rich in methane, is generated as a valuable by product. Methane produced is about 0.15 to 0.35 Nm3/kg COD destroyed.

* Owing to the compactness of UASBR , absence of mechanical/moving components, energy efficiency of the process, and reduced post- treatment and sludge handling requirements, both the capital cost and running cost of a UASBR based treatment plant are significantly less than for a fully aerobic teratment plant.

* Once a UASBR has been put in operation, acclimatised bacteria can survive without food in the reactor for long durations. This enables easy strartup of the UASBR after prolonged periods of being out of operation.

* UASBR is a noiseless, closed and covered unit that is aesthetically very satisfying.

UASBR APPLICATIONS:

UASB Technology has found applications worldwide, in treating various types of wastewater. Among industries, some popular applications are in the food processing and producing industries, dairies and milk-processing units, sugar mills, pulp and paper, breweries, distilleries, potato, vegetable and fruit processing plants, soft drink plants, tanneries and slaughterhouses. For complex industrial wastes or adverse environmental conditions, however, a pilot study or treatability assessment is desirable. For municipal waste waters (Sewage) BOD removal of 60% to 80% is normal under favourable conditions (influent BOD >=140 mg/l. BOD/COD => 0.4, temperature 15-42 ºC, etc.) Suspended solids may be also reduced in the process, but some post-treatment (aerated lagoon or stablization/polishing pond) is generally needed for BOD removal to the desired degree.

Hi Dr. Singh,

I’ve found this Article very informative and simple, which makes it easy to understand. The only thing missing is a Graphical Representation of the UASBR.. Query ; How is Water fed into this Reactor? How does water gets pushed upwards?

It will have to be at a pressure higher than the liquid co;umn in UASB. This can be possibly done by providing adequate geostatic height for pretreatment tank?

Hey,

I think you’ll need a pump before the UASBR.

As it is a continuous process, is it critical if you stop the reactor running from time to time???

Best regards,

Robert.